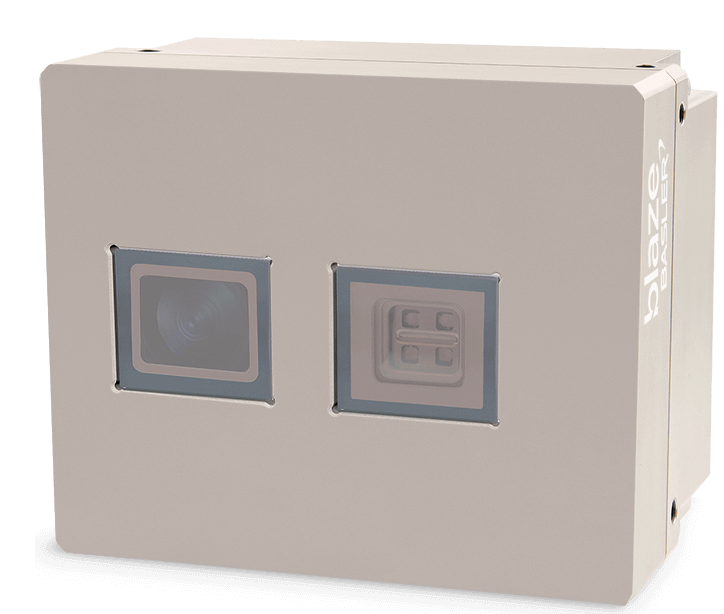

blaze-101#

Specifications#

General Specifications#

| blaze-101 | |

|---|---|

| Sensor Type | Sony IMX556 Area Scan CMOS (Time-of-Flight) |

| Measuring Method | Time-of-Flight |

| Resolution (H x V Pixels) | 640 x 480 (full resolution) |

| Resolution | VGA |

| Field of View (H x V) | 67° x 51° To calculate the field of view in millimeters, see the Scan3dFocalLength topic. |

| Range | Short: 0.3–1.5 m Long: 0.3–10 m |

| Accuracy (typical) | ±5 mm (0.5–5.5 m) (For more information, see Accuracy Test Conditions.) |

| Temporal Noise (typical) | <1.0 mm (up to 5.5 m) (For more information, see Accuracy Test Conditions.) |

| Frame Rate | 20 fps (Default) 30 fps (FastMode) |

| Latency | <85 ms |

| Synchronization | Free run, PTP IEEE 1588, software trigger, hardware trigger |

| Illumination | VCSEL, 940 nm |

| Ambient Light Robustness | Ambient light: max. irradiance 12.8 W/m² @ 920–970 nm (For more information, see Ambient Light Robustness Test Conditions.) |

| Multi-Camera Operation | Yes; via Multi-Camera Channel or PTP |

| Communication Interface | Gigabit Ethernet (1000 Mbit/s) |

| Pixel Formats | Depth Map: Coord3D_C16, Mono16, Coord3D_ABC32f Intensity Image: Mono16 Confidence Map: Mono16, Confidence16 Point Cloud: Coord3D_ABC32f |

| Exposure Time Control | Programmable via the camera API |

| Camera Power Requirements | 24 VDC (±10 %) supplied via the camera's power connector <15 W mean @ 24 VDC <55 W peak @ 24 VDC |

| Rated Power According to UL 62368-1 | max. 15 W |

| Rated Current According to UL 62368-1 | max. 0.63 A @ 24 VDC |

| Cooling | Passive, no fan |

| Enclosure Rating | IP67 (EN60529) |

| Size (W x H x L) | 99.6 x 80.6 x 63.1 mm |

| Weight | <690 g |

| Conformity | Certification Marks: CE (includes RoHS), EAC, UKCA, UL Listed, FCC, KC Electromagnetic Compatibility Emission: EN 61000-6-4; FCC (2006) Part 15, Subpart B Electromagnetic Compatibility Immunity: EN 61000-6-2 (including EN 61000-4-2, EN 61000-4-4, EN 61000-4-5, EN 61000-4-6, and EN IEC 61000-4-3 with increased signal amplitude of 24 V/m if suitable cables are used; for details see Cable Requirements) Shock & Vibration: EN 60068-2-27, EN 60068-2-6, EN 60068-2-64 (for details see Stress Test Results) Laser Safety: Laser Class 1 (EN 60825-1:2014+A11:2021, IEC 60825-1:2014) Vision Standards: GigE Vision, GenICam, GenTL Certificates for your camera model For more information, see the Compliance section of the Basler website. |

| Software | pylon Software Suite (version 6.2 or higher) pylon Supplementary Package for blaze |

| Operating System | Windows 10 Windows 11 Linux x86_64 (tested under Ubuntu 18.04, 20.04, and 22.04) Linux ARM |

| Programming Languages | C++, Visual Basic, C#, Python |

| Accessories | Accessories for your camera model |

Accuracy Test Conditions#

The accuracy was measured under the following conditions:

- Camera at default settings

- Stable operating temperature (20 minutes camera warm-up time)

- Flat, white target with 90 % reflectivity

- No ambient light

- 22 °C room temperature

- 40 x 40 pixels in the center of the sensor

- Averaged over 25 images

For more information about accuracy and repeatability, see the Accuracy and Precision topic.

Ambient Light Robustness Test Conditions#

The ambient light robustness was measured under the following conditions:

- Flat, white target with 90 % reflectivity

- Target illuminated by 940 nm LED

- 6 m distance between target and camera

- Exposure time of 250 µs

For more information about the measurement setup and test results, see the Ambient Light Robustness topic.

Laser Illumination#

Characteristics#

The blaze camera is equipped with VCSEL (vertical cavity surface-emitting lasers) that emit invisible, near-infrared laser light. The camera is classified as a Class 1 laser product according to IEC 60825-1:2014, EN 60825-1:2014, and EN 60825-1:2014/A11:2021. Furthermore, the emission limits of EN 60825-1:2007 (withdrawn) are met during normal operation.

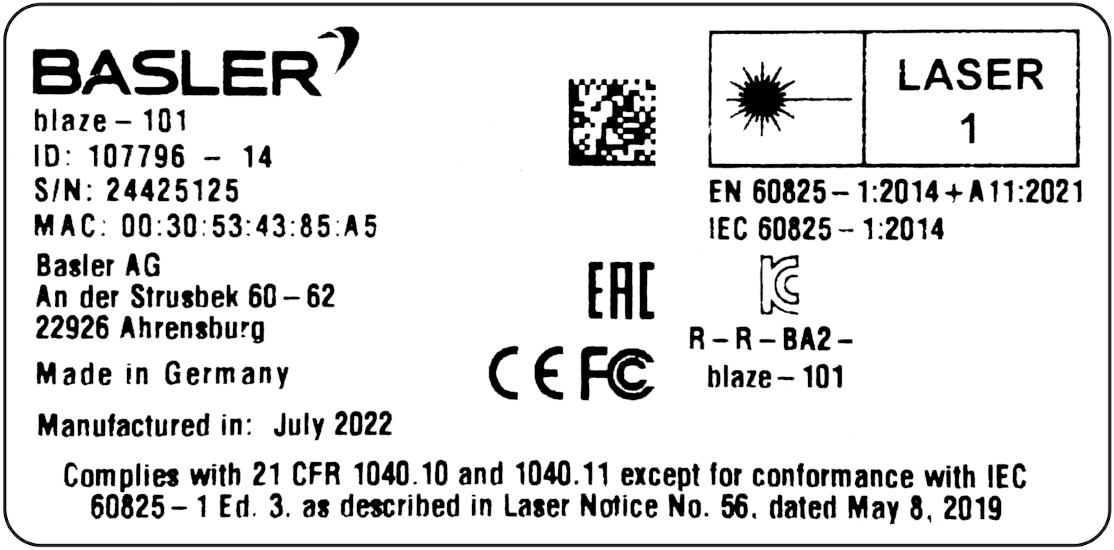

Certification Information Printed on the Product Label#

IEC 60825-1:2014, EN 60825-1:2014, and EN 60825-1:2014/A11:2021

Complies with 21 CFR 1040.10 and 1040.11 except for conformance with IEC 60825-1:2014 Ed. 3, as described in Laser Notice No. 56, dated May 8, 2019

The location of the laser aperture and the beam angle of the laser are shown here.

Laser Safety#

The camera is classified as a Class 1 laser product. This means that it is safe under all reasonably foreseeable conditions of normal use.

The technical safety elements described below (electric power control, optical diffusors, and cover glass) ensure that the accessible emission stays within safe limits. Their correct function is guaranteed by quality management measures that include a 100 % test after assembly.

Electric Power Control#

The camera is equipped with electronic safety circuitry that turns off the laser illumination within 1 ms or less when excess electrical power consumption of the illumination is detected.

Optical Diffusors#

Diffusors are optical elements mounted at the laser aperture of each VCSEL. They act both as beam shapers and as beam attenuators. Their presence is required to reduce the accessible emission to safe limits. Under normal operating conditions, Basler regards the failure of a diffusor as unlikely beyond the point of what can reasonably be foreseen.

However, in cases of severe damage to the camera (e.g., caused by mechanical stress beyond the specified limits or unauthorized modification), the failure of a diffusor can't be ruled out definitively. In case of a diffusor failure, observe the warning information in the Safety Instructions (blaze).

Cover Glass#

The VCSEL are shielded by a cover glass. This prevents users from accidentally touching the surface of the VCSEL and ensures a minimum distance to the eyes.

Product Label#

This is a sample of the product label affixed to every blaze-101 camera. Details like MAC address and serial number will vary from camera to camera.

Mechanical Specifications#

Camera Dimensions and Mounting Points#

The following graphic shows the camera's dimensions and mounting points as well as the location of the laser aperture and the beam angle of the laser. Note that the camera's field of view is different from the angles depicted here.

→ Download the CAD/technical drawing for your Basler camera.

Assembly Instructions

When mounting the camera, observe the following:

- Make sure that the camera is attached securely to a suitable mounting body using at least two M4 screws.

- Ensure a thread engagement of at least 5 mm and no more than 6 mm.

Stress Test Results#

→ See Stress Test Results.

Coordinate System of the Camera#

The blaze-101 camera uses a right-handed coordinate system with the y axis pointing down. The origin of the coordinate system is located in the optical center inside the camera housing.

Due to mechanical tolerances of the sensor, the lens, and their position to each other, there are small variations in the exact origin for each individual device.

The position of the optical center is determined by the focal length of the lens and the point where the optical axis and the sensor intersect. This intersection is called the principal point. It is close to the pixel in the center of the sensor but due to mechanical tolerances there are small variations in its exact position. To determine the exact position, get the values of the Scan3dPrincipalPointU and Scan3dPrincipalPointV parameters.

The optical center is situated along the optical axis. The distance from the principal point (in pixels) is dependent on the focal length (in pixels), which you can determine by getting the value of the Scan3dFocalLength parameter.

If your application requires working with coordinates and distances relative to the front of the camera housing and not the optical center, you can use the ZOffsetOriginToCameraFront parameter to determine the distance between the optical center and the front of the camera housing. See Processing Measurement Results to find out how to perform this transformation of coordinates.

Info

Many common point cloud processing tools, e.g., MeshLab and CloudCompare, also use right-handed coordinate systems, but with the y axis pointing up. Because of this difference in the orientation of the y axis, these tools show point clouds produced by the blaze-101 camera backwards and upside down.

To make the point clouds compatible with these tools, they need to be rotated along the x axis by 180°. This is equivalent to multiplying the y and z values by -1. This is illustrated in the Save Point Cloud sample that is included in the pylon Supplementary Package for blaze.

Alternatively, you can use the Save Depth and Image Data feature of the blaze Viewer, which allows you to have this rotation done automatically when saving a point cloud to file. By selecting the Invert z-axis check box (enabled by default), the point clouds will be made compatible with the aforementioned tools.

For more information about this feature, see Saving Depth and Image Data.

Requirements#

Hardware Requirements#

- Basler blaze-101 camera

- Power supply

- GigE cable

- Camera bracket

- Computer with a GigE-compatible network adapter, e.g., Intel Pro 1000

Software Requirements#

-

Operating system

- Windows 10, Windows 11

- Linux x86_64 (tested under Ubuntu 20.04, 22.04, and 24.04)

- AArch64 Linux (binaries built with Linaro gcc 7.3.1 toolchain; tested under Linux for Tegra)

-

pylon Software Suite

This includes all necessary drivers as well as useful tools. - pylon Supplementary Package for blaze

The supplementary package is an extension to the pylon Software Suite and provides support for Basler blaze cameras. It is available for Windows and Linux operating systems and includes the following: - blaze Viewer

- pylon C++ Instant Camera class for blaze cameras

- pylon .NET parameter lists for blaze cameras

- blaze-specific C++, C#, VB, and Python programming samples

- Robot Operating System (ROS) driver for blaze cameras

- Sample scripts for MVTec HALCON

Info

The pylon Software Suite and the pylon Supplementary Package for blaze replace the Basler blaze SDK. Although the Basler blaze SDK will continue to be available to allow users to maintain existing applications, Basler strongly recommends using the pylon Supplementary Package for developing new applications.

Electrical Requirements#

WARNING – Electric Shock Hazard

Unapproved power supplies may cause electric shock. Serious injury or death may occur.

You must use a camera power supply that meets the Safety Extra Low Voltage (SELV) and Limited Power Source (LPS) requirements.

WARNING – Fire Hazard

Unapproved power supplies may cause fire and burns.

You must use a camera power supply that meets the Limited Power Source (LPS) requirements.

NOTICE – Incorrect voltage can damage the camera.

You must supply camera and I/O power within the safe operating voltage ranges specified below.

NOTICE – Incorrect plugging in and unplugging of the camera's power cable can damage the camera.

To avoid switch-on surges damaging the camera, only plug in the power cable into the camera's power connector or unplug it from the connector if the power supply is switched off.

Camera Power#

Power must be supplied to the camera via the power connector. For information about the connector pin assignments, see Connector Pinout.

| Voltage Requirements | Max. Power Consumption |

|---|---|

| 24 VDC (±10 %) | <15 W mean @ 24 VDC Typical: 12.5 W mean @ 24 VDC <55 W peak @ 24 VDC Typical: 39 W peak @ 24 VDC |

For more information about supplying power, see Choosing a Power Supply.

Environmental Requirements#

Temperature and Humidity#

| Housing temperature during operation | 0–50 °C (32–122 °F) |

| Humidity during operation | 20–80 %, relative, non-condensing |

| Storage temperature | -20–80 °C (-4–176 °F) |

| Storage humidity | 20–80 %, relative, non-condensing |

| Housing temperature according to UL 62368-1 | max. 70 °C (158 °F) |

| Ambient temperature according to UL 62368-1 | max. 30 °C (86 °F) |

Info

Temperature has a significant impact on the performance of the camera. For more information, see the Temperature topic.

Heat Dissipation#

→ See Providing Heat Dissipation (blaze).

Cable Requirements#

Ethernet Cable#

- Use a high-quality Ethernet cable. Use of shielded CAT 5e or better cables with S/STP shielding is recommended.

If your application requires immunity to electromagnetic fields of more than 10 V/m, shielded CAT 5e or better cables with S/STP shielding are mandatory. - Use either a straight-through (patch) or a cross-over Ethernet cable.

- As a general rule, applications with longer cables or applications in harsh EMI conditions require higher category cables.

- Proximity to strong magnetic fields should be avoided.

- Basler recommends using Ethernet cables from the Basler Accessories range:

Power and I/O Cable#

- The cable must be shielded.

- The cable must have a cross-section of at least 0.2 mm² (close to AWG24).

- Maximum recommended cable length: 10 m

- Camera-side connector: M12 8-pin A-coded

- Basler recommends using cables from the Basler Accessories range:

Physical Interface#

Camera Connectors and LEDs#

Ethernet Connector#

- M12 8-pin X-coded female connector

- Used to provide a 1000 Mbit/s Ethernet connection to the camera

- Mating connector according to IEC 61076-2-109 standard, "8-pin X-coded male", e.g., Bulgin PXMBNI12FIM08XSCPG9

Power Connector#

- M12 8-pin A-coded female connector

- Used to provide power to the camera

- Mating connector according to IEC 61076-2-101 standard, "8-pin A-coded male", e.g., Bulgin PXMBNI12FIM08ASCPG7

LED States#

| Camera State | Status LED | Ethernet LED |

|---|---|---|

| No power | Off | Off |

| Powered, camera booting | Green | Red |

| Powered, camera ready for use | Flashing green | Red |

| Powered, network connection in progress | Flashing green | Alternating green/red flashing |

| Powered, network connection established | Flashing green | Green |

| Powered, network connection insufficient | Flashing green | Yellow |

Connector Pinout#

Ethernet Connector#

Power Connector#

| Pin Number | Ethernet Connector | Power Connector |

|---|---|---|

| 1 | Bidirectional Data Pair A+ | Camera Power VCC |

| 2 | Bidirectional Data Pair A- | Camera Power Ground |

| 3 | Bidirectional Data Pair B+ | Camera Power Ground |

| 4 | Bidirectional Data Pair B- | Opto-coupled I/O output line |

| 5 | Bidirectional Data Pair D+ | Ground for opto-coupled I/O lines |

| 6 | Bidirectional Data Pair D- | Opto-coupled I/O input line |

| 7 | Bidirectional Data Pair C- | Camera Power VCC |

| 8 | Bidirectional Data Pair C+ | Reserved, do not connect |

Info

Always connect both Power VCC and Power GND pins.

Precautions#

→ See Safety Instructions (blaze).

Installation#

→ See Camera Installation (blaze).

Features#

→ See blaze Features.