daA4200-30mci#

Variants#

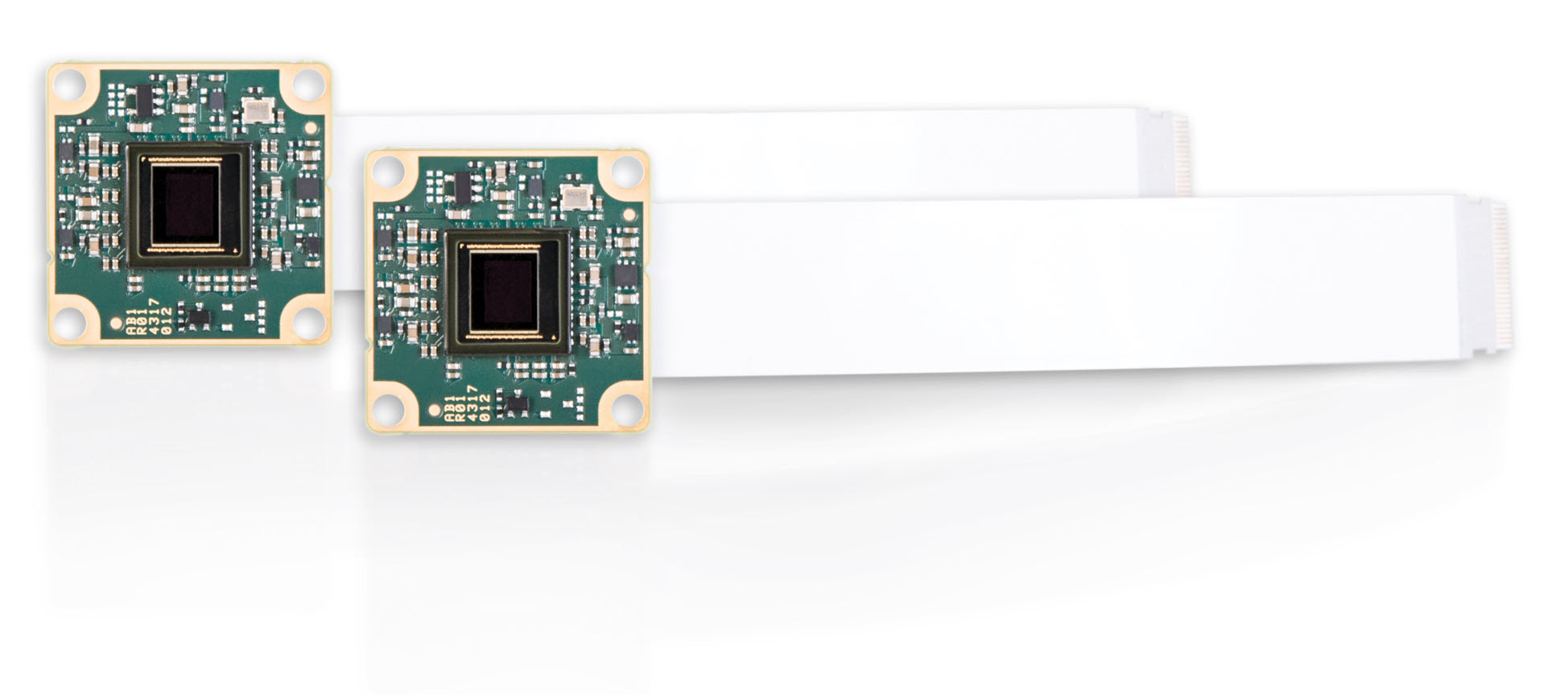

The daA4200-30mci is available in the following variants:

- Bare board: Consists of a circuit board only.

- S-mount: Consists of a circuit board and a camera front. S-mount lenses can be mounted in the lens mount on the camera front.

Info

Basler dart S-mount color cameras are not equipped with an IR cut filter. If you want to operate a Basler dart S-mount color camera with an IR cut filter, you must attach a lens with an integrated IR cut filter to the camera.

Specifications#

General Specifications#

| daA4200-30mci | |

|---|---|

| Resolution (H x V Pixels) | 4208 x 3120 |

| Resolution | 13 MP |

| Sensor Type | onsemi AR1335 Progressive scan CMOS Rolling shutter |

| Sensor Format | 1/3.2" |

| Effective Sensor Diagonal | 5.76 mm |

| Pixel Size (H x V) | 1.1 μm x 1.1 μm |

| Frame Rate (at Default Settings) | 30 fps |

| Mono / Color | Color |

| Pixel Formats | See Pixel Format. |

| Synchronization | Via hardware trigger (if supported by SoC) Via free run |

| Exposure Time Control | Programmable via the camera module's API |

| Camera Power Requirements | 1.35 W (typical) @ 5 VDC & 1200 MBit/s |

| Lens Mount | S-mount, without mount (bare board) |

| Size (L x W x H) | Bare board model: 5.3 mm x 27 mm x 27 mm S-mount model: 17.5 mm x 29 mm x 29 mm |

| Weight | S-mount model: <10 g Bare board model: <5 g |

| Conformity | CE (includes RoHS), EAC, UKCA, FCC, UL Listed, GenICam 2.4 (including PFNC 1.1 and SFNC 2.1), KC Certificates for your camera model For more information, see the Compliance section of the Basler website. |

| Accessories | Accessories for your camera model |

| Availability and Pricing | See the product page on the Basler website. |

Spectral Response#

The spectral response curve excludes lens characteristics and light source characteristics.

IR Cut Filter#

To achieve best camera performance, Basler recommends using a dielectric IR cut filter.

The filter should transmit in a range from 400–≈700 nm, and it should cut off from ≈700–1100 nm.

- For the bare board variant, Basler recommends installing an IR cut filter or a lens with an integrated IR cut filter when integrating the camera into the system.

- For the S-mount variant, Basler recommends attaching a lens with an integrated IR cut filter to the camera.

Mechanical Specifications#

Dimensions and Mounting Points#

Bare Board Variant#

→ Download the CAD/technical drawing for your Basler Camera.

S-Mount Variant#

→ Download the CAD/technical drawing for your Basler Camera.

Maximum Allowed Lens Intrusion#

→ See Maximum Allowed Lens Intrusion.

Stress Test Results#

→ See Stress Test Results.

Requirements#

Environmental Requirements#

Temperature and Humidity#

| Description | Bare Board Variant | S-Mount and CS-Mount Variant |

|---|---|---|

| Device temperature during operation | 0–75 °C (32–167 °F)a | 0–50 °C (32–122 °F)b |

| Device temperature during storage | -20–80 °C (-4–176 °F) | -20–80 °C (-4–176 °F) |

| Humidity | 20–80 %, relative, non-condensing | 20–80 %, relative, non-condensing |

| Ambient temperature according to UL 60950-1 | max. 50 °C (122 °F) | max. 50 °C (122 °F) |

-

Temperature measured at the temperature measurement point, i.e., at the hottest point on the board. This point is significantly hotter than the other parts on the board.

-

Temperature measured at the temperature measurement point, i.e., at the camera front.

Heat Dissipation#

→ See Providing Heat Dissipation (dart).

Physical Interface and Electrical Requirements#

→ See BCON for MIPI Interface Description.

Cable Requirements#

→ See BCON for MIPI Hardware Design Guide.

Precautions#

→ See Safety Instructions.

Installation#

→ See Installation.

Features#

→ See Features.